Concrete Pathway Highland Park Experts

Build concrete that meets Highland Park's climate demands and code requirements. Our process includes drainage grading, subbase compaction, and placement of air‑entrained, low w/c mixes with fiber additives, calculated joint positioning, and proper concrete cover per ACI/IDOT standards. Count on superior freeze‑thaw durability, salt‑resistance, and slip‑resistant finishes for all concrete installations from driveways to patios. We handle all aspects including permits, engineer-stamped plans, inspections, and detailed timeline management, including documented Highland Park best Concrete Contractor mix designs, pour tickets, and RFIs. We conduct repairs and overlays using strict quality control and curing standards. Learn how our thorough process ensures lasting value.

Key Points

- Local Highland Park experts: oversee permits, inspections, and local regulations, providing approved technical drawings and comprehensive weekly updates on progress, safety, and quality.

- Robust, weather-proof concrete: including air-entrained mixtures, optimized w/c proportions, supplementary cementitious materials, proper curing techniques, freeze-thaw protection and salt damage prevention, and ultraviolet-stable, slip-resistant coating systems.

- Accurate site prep and drainage: confirmed elevations, 2% slopes, densified subgrade, geofabrics, vapor protection, and infrastructure/right-of-way documentation to minimize settling and dampness concerns.

- Strong, code-compliant slabs: reinforced with #4/#5 rebar, joints installed to ACI/ASTM standards, correct concrete cover, structural connectors, and temperature barriers to minimize movement and thermal bridging.

- Clear schedules and costs: Our system features detailed Gantt charts and timelines, instant weather conditions and inspection notifications, comprehensive pricing details including quantity and unit rates, and shared logs for all project communications including RFIs, submittals, tickets, and project changes.

The Importance of Local Knowledge in Highland Park

Although concrete standards are consistent everywhere, Highland Park's unique environmental conditions and local regulations call for local expertise to construct properly the first time. You need a contractor who understands expansive clay, knows about freeze‑thaw cycles, and selects mixes, reinforcement, and jointing that meet local performance criteria. With regional expertise, a specialist maps drainage patterns, utility easements, and right‑of‑way constraints that impact slab thickness, base prep, and placement timing. They also streamline permit navigation, submitting stamped plans, arranging inspections, and conforming work with Highland Park ordinances and IDOT references. You'll eliminate delays, rework, and violations because aspects like air‑entrainment, curing windows, and salt‑exposure mitigation are handled up front. Local expertise transforms code into constructible solutions-on schedule, as planned, and prepared for review.

Professional Driveway Planning and Installation

First, tackle site grading basics to control proper water flow, frost protection, and required gradients. Subsequently, determine appropriate reinforcement-fiber, rebar, or welded wire mesh to reduce cracking and accommodate vehicle loads based on local codes. Lastly, select finishes—broom, exposed aggregate, or sealed smooth that balance safety, appearance, and upkeep.

Site Grading Fundamentals

Before concrete installation begins, proper site grading establishes the basis of a long-lasting, regulation-compliant driveway. Current elevations must be verified, determine finished elevations, and establish slopes-generally 2%-to channel water from buildings and to designated drainage points. The base layer is shaped to prevent dips, then compact the soil to proper density specifications, validating results with on-site testing. Properly prepared subgrade eliminates settling, fractures, and water pooling.

You integrate drainage swales alongside property lines to collect runoff, connecting them to municipal drainage systems as per municipal requirements. Adjacent properties are protected by controlling water flow and stopping soil loss with sediment management. Required spacing is preserved at garages, sidewalks, and utilities, while checking setback requirements. Once grades are established, layout verification is completed prior to foundation work and pour coordination.

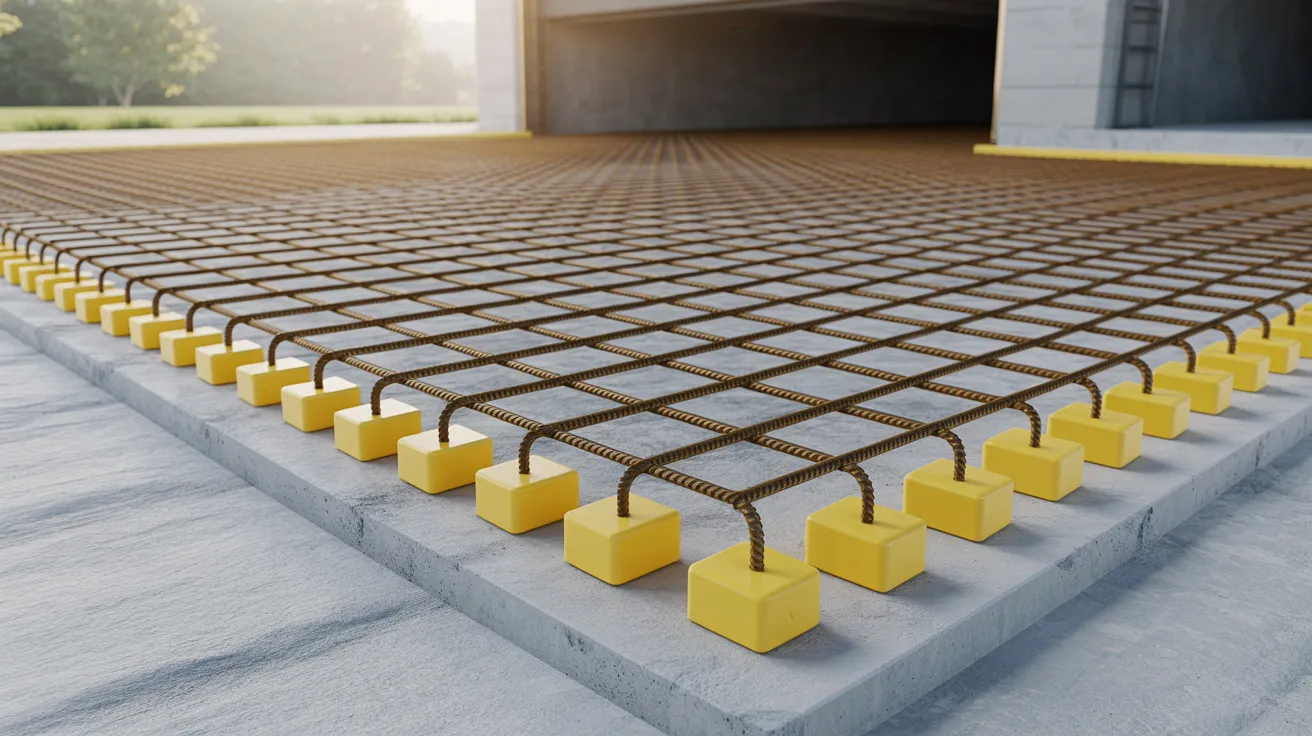

Strengthening and Surface Treatments

With grades verified and the subgrade stable, specify reinforcement and surface applications that conform to Highland Park standards and project load demands. Select #4 or #5 bars at 18-inch centers, or welded wire mesh per specifications, and fasten junction points to ensure adequate cover. Rebar placement must provide a minimum 2 inches of bottom cover and clear spacing from expansion joints, utilities, and driveway apron dowels. Place steel chairs, not stones, to support steel. Anchor driveway-to-garage connections with epoxied dowels where specified.

Place concrete at the specified slump, consolidate edges, and create control joints at 10-12 feet spacing or 24-30 times slab thickness within the first 6-12 hours. Implement finishing techniques that enhance traction and durability: drive lanes with broom finish, borders with troweled-and-broom finish, and moisture retention through wet cure or compound for a week-long duration.

Pool Decks, Patios, and Outdoor Entertainment Areas

You want lasting outdoor spaces that look clean and work year-round. We specify durable patio materials-strengthened concrete, fiber enhancement materials, and protective sealants-that resist wear, staining, and crack formation. For swimming pool surrounds, we apply anti-slip texturing and treatments that enhance surface grip in wet conditions without sacrificing comfort and water flow.

Durable Patio Materials

Hardscape materials like stone, concrete, and composites are essential for outdoor entertainment areas, pool decks, and patios that must withstand environmental exposure, foot traffic, and temperature cycles. It's essential to use solutions providing demonstrated strength and environmental protection. Choose concrete with air entrainment and fiber additives and suitable foundation work to minimize deterioration. Use long-lasting paver systems with polymeric sand joints to direct runoff. Choose environmentally conscious composites featuring UV-resistant recycled materials that resist degradation or need frequent maintenance.

Ensure proper drainage with 1/8-1/4 inch per foot slope away from structures, combined with perimeter edging and geotextile separation over compacted aggregate. Choose sealers specifically rated for handling deicing salts and UV exposure. Insist on ASTM/ACI compliance and detailed warranties to secure reliable long-term performance.

Non-Slip Pool Decks

Beyond material durability, pool deck surfaces need to safeguard swimmers from slip hazards. You need a deck that meets safety standards without sacrificing aesthetics. We utilize anti-slip materials with tested slip resistance ratings, apply textured coatings for reliable grip when wet, and carefully plan joint patterns to prevent stumbling. We incorporate water management systems-effective gradients, linear drains, and subtle water routing-to move water off the surface quickly and prevent moss formation.

We provide UV-stable sealers that guard against chlorine and salt, plus heat-resistant materials that limit heat absorption. We restore spalls, refinish worn concrete, and install broadcast aggregates in locations enhanced slip resistance is necessary. Movement joints, coping adaptations, and handrail anchors are installed per code. The result is a hassle-free, secure, and attractive pool deck engineered for daily use.

Walkways, Sidewalks, and Property Enhancement Solutions

A damaged or irregular walkway can diminish the look and security of your property, skillfully built walkways and pathways instantly boost curb appeal and functionality. We assess elevation, drainage patterns, and Highland Park requirements, then implement suitable substrate, forms, reinforcement, and control joints for durable, safe surfaces. You may choose brushed, aggregate, or impressed designs that balance traction and style.

To enhance visibility and compliance, we implement carefully painted curb markings at corners and accessibility ramps as required. Thoughtful landscaping elements create clear boundaries, protect concrete from soil erosion, and channel walking paths. Subtle lighting fixtures, weather-sealed perimeters, and properly spaced expansion gaps ensure easy maintenance. You receive a unified entrance sequence that guides visitors, stands up to weather, and enhances your property's curb appeal without overbuilding.

Foundations, Slabs, and Structural Concrete

For both new construction and existing structure stabilization, we create and implement foundations and slabs that fully comply with Highland Park codes, soil conditions, and structural loads. We carefully analyze geotechnical reports, recommend appropriate soil stabilization when needed, and detail the appropriate rebar, post-tensioning, or grade beams to control movement and cracking. You can expect accurate elevations, vapor barriers, and properly placed control joints in accordance with ASTM and ACI standards.

In slab-on-grade construction, we verify subbase compaction, moisture control, and proper drainage away from the structure. We choose mix designs to ensure strength, durability, and climate performance, and we control curing parameters to meet specified strength requirements. For basement and structural components, we set up forms, anchors, and reinforcement per plan. We incorporate thermal insulation where specified, improving energy efficiency while maintaining structural strength.

Decorative Finishes: Stamped, Stained, and Polished

From entryways to outdoor living spaces, you can transform concrete with stamped, stained, or polished finishes that align with Highland Park standards and performance expectations. You'll choose materials, textures, and safety features that align with local standards and application areas.

For stamped concrete projects, we specify precise mix formulations, joint placement, and textural details to emulate masonry, brick patterns, or wood grain while ensuring proper water drainage and cold-weather resistance. Built-in coloring and sealant application maintain color integrity and prevent sun fading.

For stained floor surfaces, we carefully assess substrate moisture levels, choose between acid-based or water-based treatments, and implement densifiers for better wear resistance. All edges and transition points remain ADA-compliant.

For polished concrete surfaces, we establish detailed cutting sequences, image clarity goals, and protective measures. You'll receive a long-lasting, simple-to-maintain surface that delivers both function and sophistication.

Maintenance, Repair, and Resurfacing Solutions

Seemingly insignificant fractures and damage can deteriorate into serious structural concerns if not addressed, so we meticulously identify source issues and perform code-compliant repairs customized for Highland Park conditions. We reinforce substrates, restore profiles, and reestablish proper drainage to protect adjacent structures and utilities. For small, non-moving fractures, we utilize crack injection to restore monolithic performance and stop moisture infiltration. Where delamination or scaling occurs, we grind and overlay with bonded overlays, maintaining correct slopes and control-joint layout.

We'll provide a maintenance schedule that covers comprehensive surface maintenance, joint repair, and protective coating to prevent damaging elements and wear. We record all maintenance activities, provide warranty protection, and verify compliance with city requirements. Our structured maintenance program prolongs durability and decreases lifecycle costs.

Materials, Methods, and Weather-Resistant Solutions

These maintenance protocols only work effectively when you pair them with the right mix designs, placement methods, and weather controls designed for Highland Park. Begin by utilizing air-entrained mixtures with reduced w/c ratios, durability-enhancing SCMs, and approved admixtures for setting time control. For structural elements, specify proper reinforcement cover and joints per ACI 318 and ACI 360. Where cold formed concrete assemblies are detailed, align anchoring requirements, curing procedures, and fastener selection to avoid crack development.

You apply temperature‑controlled subgrades, implement vapor barriers where required, and complete using slip‑resistant textures. Moisture retention covers, temperature-controlled molds, and climate-controlled environments ensure hydration at optimal levels. You establish thermal bridging mitigation at slabs, balconies, and edges using thermal breaks. Ice-melt restriction protocols, sealants, and joint cutting schedules decrease scaling and joint raveling.

Clear Scheduling, Pricing, and Project Updates

Clear outcomes begin with clear expectations, which is why we incorporate transparency into all steps: a comprehensive baseline schedule with critical path milestones, team deployments, and inspection checkpoints; a complete scope defining inclusions/exclusions; and a itemized estimate linked to quantities, unit rates, and contingencies. You'll get clear estimates that define assumptions, alternates, and allowances, ensuring pricing matches drawings, specs, and applicable codes. We maintain a Gantt schedule and share real-time updates when external factors, inspections, or utility locates influence sequencing. You can examine submittals, mix designs, and pour tickets in a shared log. We record RFIs, change orders, and field directives with impacts to time and cost. Weekly check-ins validate progress, safety, testing, and punch action items-guaranteeing reliable results without surprises.

Frequently Asked Questions

Are You Properly Licensed, Bonded, and Insured for Highland Park Operations?

Our company is fully licensed, bonded, and insured for operations in Highland Park. You get licensed professionals familiar with local codes and permitting. Insurance verification and bonding information are available when needed, along with license numbers for your due diligence. Our coverage includes general liability and workers' compensation insurance, and we can add you as a certificate holder. Feel free to confirm our status via city or state verification systems. Our focus remains on compliance, safety, and clear documentation.

What Warranty Coverage Do You Provide for Materials and Work

We provide explicit warranty coverage for Materials and Workmanship. Consider this fact: strong guarantees show our commitment. We guarantee materials according to manufacturer terms-usually 2-5 years-fully documented and transferable as appropriate. We offer a one-year guarantee, protecting against problems with installation and finishing, conforming to local codes and ASTM standards. You'll receive detailed warranty documentation, containing warranty terms, exclusions, and claims details. Should issues arise, reach out to our team; we'll assess, fix, and confirm proper resolution.

What's Your Process for City Permits and Inspections?

We handle all required documentation and inspections for you. We develop fully compliant documentation, handle permit submissions, and follow permit timelines with the city. We handle timing of inspections, attend all onsite inspections, and address any comments quickly. You'll get notifications at all critical points-submission, approval, preliminary, and final. If any revisions are needed, we immediately provide updated documents. We keep current complete documentation and insurance coverage the city requires, making certain your project proceeds smoothly and according to regulations.

Are Local References and Recent Project Photos Available?

Absolutely. You'll receive a handpicked list of latest projects within 5 miles, complete with dates, scopes, and client testimonials. Since 63% of homeowners feel dissatisfied about hiring without seeing proof, we showcase professional project photos, before-and-after sets, and material specs. We provide accessible references, permit numbers, and inspection approvals for verification. When asked, we'll schedule site walk-throughs and send a secure link to a collection organized by project type, code requirements, and finish options.

How Do You Handle Change Orders and Unexpected Issues?

We provide formal change documentation for all scope changes, with transparent costs and authorized by you before moving forward. Unforeseen issues trigger contingency planning: we assess root cause, suggest conforming fixes, adjust timeframes and expenses, and maintain detailed records. When issues impact structural safety or integrity, we halt operations until you validate the remedy. We monitor changes, keep detailed daily records, and coordinate inspections to maintain project oversight, conformity, and reliability.

In Conclusion

You've got goals for your property, and we've got the concrete path to make them reality. From custom concrete projects, you'll benefit from regional experience, industry-standard practices, and climate-smart solutions. We take care of design, installation, and maintenance with clear schedules, upfront costs, and steady communication-no guesswork. Whether it's a concrete installation or a polished patio, we ensure excellence in every step. Let's transform your vision into reality-durable as stone, flawless in finish.